The 3D-printable gels from North Carolina State University potentially enable new kinds of applications in biomedical materials and soft robotics.

Described in the journal Nature Communications , the water-based gels — called homocomposite hydrogels — are both strong and flexible. The 3D-printed jelly is composed of alginates chemical compounds found in seaweed and algae that are commonly used as thickening agents and in wound dressings.

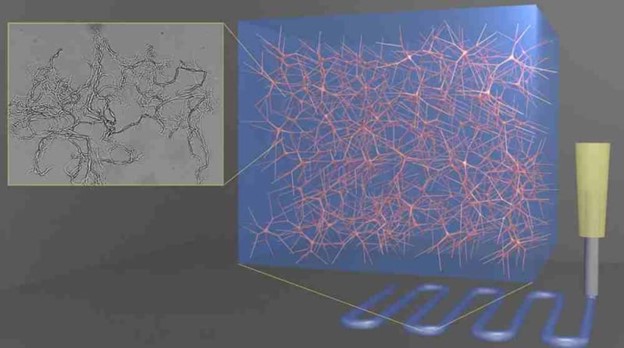

“These particles, which are made of the same densified material as the hydrogels, interlock to create an internal reinforcement network.“, as Prof. Orlin Velev mentioned.

Merging different-size scale networks of the same alginate together eliminates the fragility that can sometimes occur when differing materials are merged together in a hydrogel, says Orlin Velev, Professor of Chemical and Biomolecular Engineering at NC State and corresponding author of the paper

Future work will attempt to fine-tune this method of merging of homocomposite materials to advance 3D printing for biomedical applications or biomedical injection materials,

The most exciting aspect from this perspective is the ability to design a new class of soft matter with improved and very well controlled properties. In addition to that, this research will contribute to a number of applications in biomedical treatments, pharmaceuticals (e.g. injectable gels), soft robotic actuators, and even food products

Sources:

https://news.ncsu.edu/2021/05/researchers-develop-3d-printed-jelly/

https://www.techbriefs.com/component/content/article/tb/stories/blog/39205